Automatic Corrugated Box Folding Carton Forming Machine Auto Case Tray Erector Cardboard Tray Former Machine

Description

Basic Info.

| Model NO. | GPT-10 |

| Forming Function | Forming |

| Driven Type | Electric |

| Material Type | Tape or Glue |

| Packaging | Cartons |

| Packaging Material | Carton Erector |

| Brand | Gurki |

| Certificate | CE, SGS, BV, TUV, Intertek |

| Machine Weight | 500kg |

| Table Height | 900mm |

| Advantages | High Quality |

| Customized | Available |

| Staff | More Than 300 |

| Patents | 60+ |

| Carton Storage Quantity | 80-100PCS (800-1000mm) |

| Power | 1kw |

| Air Consumption | 200nl/mm |

| Air Compressing | 6kg/Cm³ /0.6MPa |

| Carton Size | L300-500*W150-250*H40-80mm |

| Speed | up to 15 PCS/Min |

| Transport Package | Plywood Case |

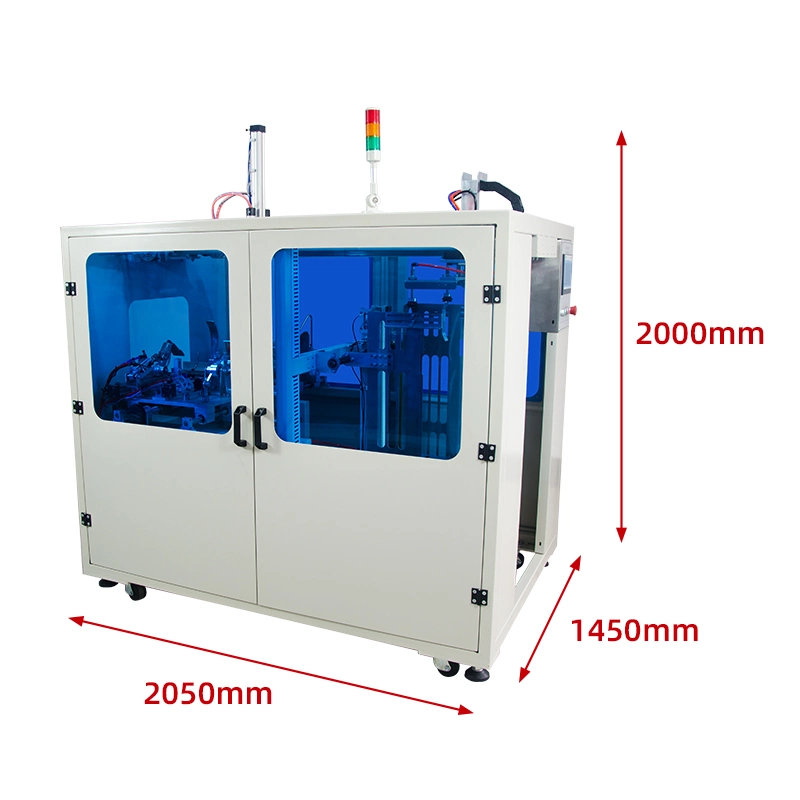

| Specification | 2050*1450*2000mm |

| Trademark | GURKI |

| Origin | Guangdong, China |

| HS Code | 8422400090 |

| Production Capacity | 1000sets/Month |

Product Description

Product DescriptionCardboard Box Manufacture Machines Automatic Pizza Box Folding Machine

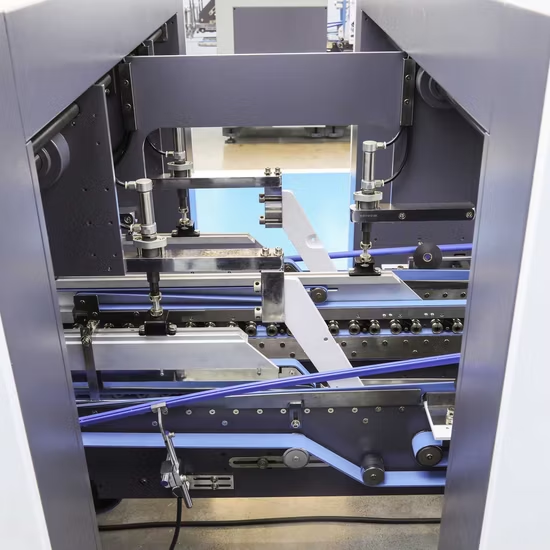

GURKI tray formers ensure square, stable loads with straight sides and properly applied glue for a consistent product. Integrating a tray forming machine in your operations can ensure reliable results for increased productivity.

| MODEL | GPT-10 |

|---|---|

| Production speed | 10-15pcs/min |

| Tray/Box Size | L300-500×W150-250×H40-80mm |

| Power Supply | 220 50HZ 1 Phase |

| Power | 1KW |

| Air Consumption | 200NL/mm |

| Air Compressing | 5-7kg/cm³ |

| Table Height | 900mm |

| Machine Dimension | L2050xW1450xH2000mm |

| Machine Weight | 500kg |

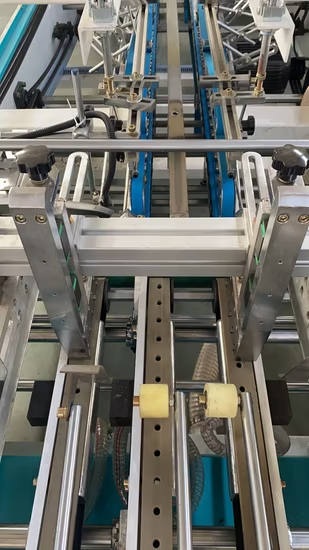

- Choice of hotmelt adhesive or lock form tray styles.

- Easy to use and adjust by operators for quick change overs.

- Ergonomic loading of packaging blanks.

- Suitable for corrugated, solid board and folding carton trays.

- Ideal for retail ready packaging.

- Reduced labour costs due to automation.

- Increased production efficiencies over manual erection.

- Reduction in packaging costs - trays sealed with hotmelt adhesive use less material.

- Improvements in operational health & safety - reduced risk of repetitive strain.

- Flexibility of production due to quick and easy size change overs.

- Maximised output due to continuous operation during replenishment of blanks.

With over 25years experience in the industry,GURKI experts in research and develop team have numerous approach on different application.With our complete facilities production plant,it allow us to offer custom madeequipment for special needs.

Gurki all adopt well-known imported brands to produce machines, to ensure the precision of each of our materials and each accessory, to ensure that the quality of the machines we produce is ahead of our industry. We invest a lot of money, we use the best equipment, only the best high-end products.

After the machine is completed, our workshop personnel will carry out multiple commissioning and inspection to ensure that the customer gets the most suitable mode. Before shipment, a quality inspection video is taken to ensure that our customers can easily install and start the machine when they get it. At the same time, we provide online installation, maintenance guidance services, up to 12 months warranty period.Oversized spare parts warehouse, we produce our own spare parts our own production machines, all accessories are tailored, adding the greatest guarantee for our machines, with sufficient spare parts inventory, so that our customers can rest assured of production.CertificationsPackaging & Shipping

FAQ

1.What's your advantage? Why we choose you?A1: 25+ Years of experience in packaging machine production and R&D. We have the most professional techniques and team, according to the customer requirements, we support customized machine.A2: We are a professional manufacturer and warmly welcome clients from worldwide to visit our factory and cooperate with us.2.What are the payment terms?A1: T/T would be better with quick transfer and few bank fees,30% deposit, balance before shipment. A2: LC could also be accepted, but the procedure is complex and the fee is high.3.What is the service?7 days 24 hours online service, engineer oversea service is also available if necessary.4.Warranty of the machine?One year warranty except for the consuming spare parts.5.What are the delivery terms?FOB Shenzhen, CNF destination port under LCL and FCL is available.6.What is the delivery time?5-30 working days after the confirmation of the order.

Our Contact