Automatic Corrugated Carton Box Folder Gluer Stitching Machine Cold Gluing Gk

Overview Product DescriptionSeries PC folding gluing machine is packet type machine, adopts advanced domestic technology

Description

Basic Info.

| Total Power | 22.28kw |

| Glue | Water-Base Cold Glue |

| Overall Dimension | 14X1.9X1.7m |

| Certification | CE ISO 9001 |

| Weight | 8-10t |

| Max.Liner Speed | 260m/Min |

| Way of Folding in Reverse | Fold 2 and Fold 4 Are 180 Degree |

| Feeding Way | Automatically and Continuously Feeding |

| Paper Material | Cardboard 210-800g, a/B/E Corrugated |

| Model | Gk-1200PC/1450PC/1600PC |

| Transport Package | Wooden Case |

| Specification | 16*2.1*1.6m |

| Trademark | GAOKE |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 20sets/Month |

Product Description

Product DescriptionSeries PC folding gluing machine is packet type machine, adopts advanced domestic technology, independent driving structure, two-purpose machine, adopts electrical regulating board, PLC, imported electronic components, feeding section adopt mechanic continuously variable, stable and easy to control and operate. The machine is especially designed for all kinds of cardboard, corrugated packaging boxes, has correction function, make corrugated boxes perfectly meet the requirements of auto packaging together. (in case of any special function required, we can design according to the customer's intention.)Product Parameters

| Name | GK-PC auto high-speed gluing folding machine | |||

| model | GK-1200PC | GK-1450PC | GK-1600PC | GK-1800PC |

| Paper Material | Cardboaed210-800g A/B/E Corrugated | |||

| Max. Liner speed | Max. 280 meter/minute | |||

| Feeding way | Automatically and continuously feeding | |||

| Way of folding | Fold 1 and fold 3 are 180°, | |||

| Glue Material | Water-base cold glue | |||

| Power Supply | 3P380V50HZ | |||

| Total power | 19kw | 20kw | 20kw | 21kw |

| Weight | 8T | 9T | 10T | 12T |

| Over dimension | 16x1.85x1.6m | 16x2.1x1.6m | 16x2.3x1.6m | 16x2.5x1.6m |

Equipment List of GK-PC

NO. | Name | QTY | Brand | |

| 1 | Wallboard of the Host | 1*2 | 20mm National Standard Steel Plate after cold and heat treatment | |

| 2 | Wallboard of the Conveyor | 1*2 | 10mm National Standard Steel Plate after cold and heat treatment | |

| 3 | Engine | Qiaobang Zhejiang | ||

| 4 | Conveyor motor | Qiaobang Zhejiang | ||

| 5 | Frequency Transformer | Rexroth German | ||

| 6 | PLC (Controller ) | FATEK Taiwan | ||

| 7 | Touch Screen | weinview Taiwan | ||

| 9 | Breaker | Schneider France | ||

| 10 | Contact | Schneider France | ||

| 11 | Intermediate relay | Schneider France | ||

| 12 | Button | Schneider France | ||

| 13 | Switch Power | Meanwell Taiwan | ||

| 14 | Photo electricity | KEYENCE | ||

| 15 | Head Feeding Belt | NITTA Japan | ||

| 16 | Baseband Belt | NITTA Japan | ||

| 17 | Conveying Belt | Xibeike Xiamen | ||

| 18 | Synchronous belt | Gates USA | ||

| 19 | Bearing | NSK Japan | ||

| 20 | Drive Bearing | NSK Japan | ||

| 21 | Chrome Bar | Hardening and tempering | ||

| 22 | Bottoms + Remote Controller | Telecrane Bottom, 8 wireless Remote control bottom | ||

| 23 | Layer, Roller | Special produced profile, heat treatment | ||

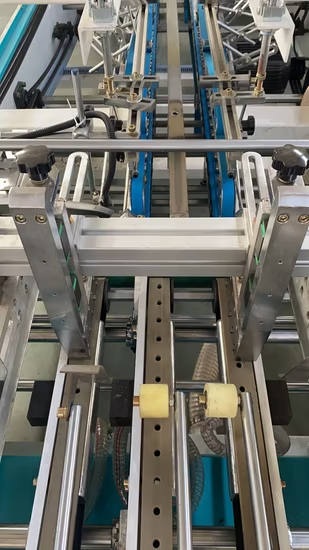

| Feeding section | |

| Equipped with air suction function, Multi-stage rail to ensure the verticality of pressing board. To ensure that the paper feeding is not skewed, the unique structure keeps more simple and convenient adjustment of pressing board. Push structure make supporting cardboard adjustment more convenient and stable. |

| Aligner section | |

| Aligner section adopts independent motor drive, equipped with automatic correction device to correct the obliquity and ensure the correct feeding. |

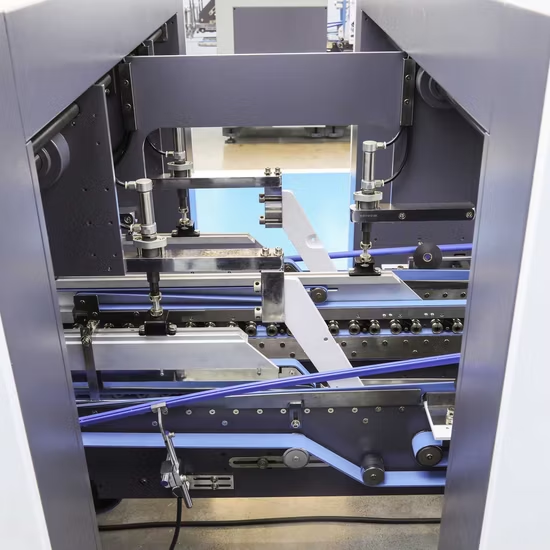

| Bottom folding | |

Independent motor drive, equipped with upper gluing tank. |

| Folding | |

| Equipped with 3 plate type rail device. The upper pressure belt adopts the main drive and cylinder pressure more suitable for different thickness corrugated products. |

| Full pressing | |

| 1.Independent motor drive can be used to control the adjustable size of the belt. 2.Paper collection adopts cylinder pressure system, easier to adjust pressure, make the box more effectively gluing. |

FAQ

1

Q:Are you manufacturer? A:Yes, we are folding gluing and window patching machine manufacturer with 10-year experience and profession.2. Where is your company located? How can I visit there?

A:Our new factory address: No.18, Wansheng, Road, Wanquan Ind. Zone, Pingyang, Wenzhou, Zhejiang, China.The nearest transportation center is Wenzhou Longwan airport or Ruian train station. 3.What's your advantages ?_machines designed to quickly adjustable

Q:What is the production time while placing order? A:About 30 days

If you have any inquiry, please don't hesitate to contact us. We will reply to youat the first time as we can.

Our Contact

Send now