Automatic Folder Gluer Packaging Line Equipment (XCS

XCS-1100AC Automatic Folder Gluer 1.Equipped with full color touch screen monitor system, the main machine, and conveyor

Basic Info.

| Model NO. | XCS-1100PC |

| Suitable Paper | 200-800GSM Cardboard, E/ F /N Corrugated Board |

| Paste | Solute Stlyle |

| Feeding Way | Automatic Continuously Feeding |

| Compressed Air | 6 Bar |

| Inching Speed | 40m/Min |

| Optional Box | 4,6 Corner Box |

| Characteristic | Prefold Folding, Lock Bottom Folding |

| Speed | Max.300m/Min |

| Function | General Side Stickers |

| Width Range | 430-1100mm |

| Length Range | 150-900mm |

| Transport Package | Wooden Packing |

| Specification | dimension(L*W*H): 15000mm*1850mm*1400mm |

| Trademark | XCS |

| Origin | Dongguan China |

| HS Code | 8422400000 |

| Production Capacity | 200/Year |

Product Description

XCS-1100AC Automatic Folder Gluer| Model | XCS-1100AC |

| Suitable paper | 200-800 g / m2 cardboard, E, F, N corrugated board |

| Box type | Straight-line box, double sides box, crash-lock bottom box |

| Feeding way | Automatic continuous air suction for paper feeding. |

| Paste type | Solute type |

| Max. speed | 300m/min |

| Power | 26KW, AC220V/380V |

| Weight | 8500kg |

| Dimension | 16500mm*1900mm*1600mm(L*W*H) |

| Inching speed | 40m/min |

| Compressed air | 6 bar |

| Air compressor capacity | 10m/3 |

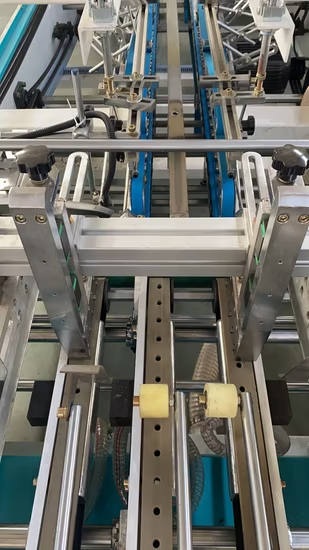

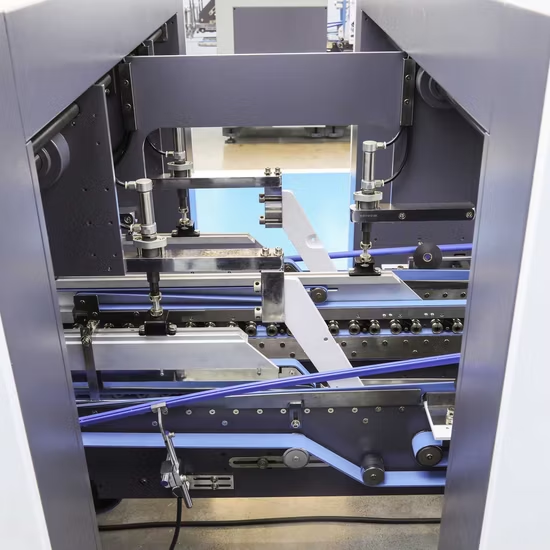

1.Equipped with full color touch screen monitor system, the main machine, and conveyor can control the speed automatically and trace the parameter setting system synchronously.2. Equipped with mobile adjustment for each plate , elaborate screw rod design, easy and fast operation by one people , high efficiency.3.High efficiency speed conversion and powerful electric motor, equipped with strong belt for power transmission, high efficiency, low voice, easy maintenance and economic benefit.4.Standard general side stick , double sides and lock bottom folding , elaborate design, easy and fast operation.5.The upper and lower glue tank equipped with unique design for special box.6. The press folding and conveyor equipped with adjustive pressure design for special products and a set of special soft belt for average pressure to ensure the perfect quality.7. Photo-electric count, viable and quantitative count, equipped with kick board identification equipment8. Electrical system:(1)Low voltage apparatus: AC relays, button, intermediate relay, fuse all are from French Schneider(2) Converter is from Taiwan Delta(3) PLC and touch screen of human machine interface are from Taiwan Delta.Feeder1. Paper feeding independent motor frequency control2. Main motor speed ratio linkage, pasting box process to keep the box spacing stable.3. Equipped with air suction, ensuring feeding accuracy.Bottom hook section1. Three carrier belt structure, and segmented upper-carrier belt, realize different boxes production.2. Modular design for bottom lock accessories, easy for adjustment.Gluing section1. Stable at high speed.2. Without glue leakage and throwing.3. Paste roller knurling treatment.Final-folding section1. Lengthening final-folding section, pneumatic adjusts pressure.2. Equipped with taper pulley (right and left) adjusts the speed of belt.3. Middle plate can be equipped with optional outer belt.1. Mini-box can be made on the left.Output section1. Upper and lower drive mechanism for lengthwise adjustment2. Equipped with belt tension automatic adjustment system3. Pneumatic lifting, can quickly adjust the pressureCounter device1. The box counter coordinates with the photo-electricity, electromagnetic valve, and cylinder. When the box go through the photo-electricity counter and up to the setting number, cylinder will kick out by the side of the neat boxes to mark for the convenience of packing.2. The photo-electricity counter and cylinder are controlled by the touch screen, and the number of each pack can be set between 0-9999, and each action time is between 0-99 second. Conveyor with pushing neat section1. Pneumatic adjustment of pressure, effective to facilitate the box paste.2. Conveyor speed according to the host speed with the photoelectric .3. Automatically or manually adjust.4. Depending on the length of the box, the upper part of the conveyor is equipped with a motor that moves back and forth.5. Pushing device can reducing the bell mouth of the box effectively.6. The paper can be delivered to paper receiving unit smoothly. About us:FQA:1. What is the machine warranty? one year.2. Does your machine with CE certificate? Yes.3. What's the payment term? A:T/T 30% in advance, the balance paid before delivery. We also accept payment L/C.4.What is the production time while placing order? About 30 days.5. What is the delivery time? Within 30 days after get the payment.6. Does the packing strong? Yes, of course! All of our export packings is with strong wooden pallets, all are confirmed to export packing standard.7. Are you manufacturer? Yes, we are manufacturer, and we have been in this field for more than 10 years.8. Do you have a stock product to sell? Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need a custom one for you, and your order will be highly attention to manufacture.9. How about after-sales service process? When your machine has a problem, contact your sales and we will solve your problem as soon as possible.10. Do you inspect the finished products? Yes, we have QC department, they will inspection the machine before shipping, to ensure there is nothing problem of the machine.11. Do you have your technical team? Yes, we have our own technical team and we have our own patents. And we can custom the machine as customer want.If you have any inquiry, please don't hesitate to contact us. We will reply to you at the first time as we can. Contact way :