Automatic Rigid Paper Box Making Machine for Luxury Box Machine

Description

Basic Info.

| Model NO. | RB600A |

| Machine Weight | 5500kg |

| Application 2 | Boxes for Shoes, Phone, Shirts, Jewelry, Gifts |

| Turn in Depth(R) | 10-100mm |

| Positioning Position | +-0.1mm |

| Cardboard Thickness | 0.8-3mm |

| Finished Box Size | Max. 400*600mm; Min.: 50*100mm; Height:12-185mm |

| Average Speed | 1000-1800PCS/Hour |

| Transport Package | Wooden Case |

| Specification | L6360*W5000*H3260mm |

| Trademark | RONGDA |

| Origin | China |

| HS Code | 84414000 |

| Production Capacity | 100 |

Product Description

Product Description

RONGDA -- Quality builds brand.

RB600A Automatic Rigid Box Making Machine

Intelligent/ Digital adjustment/ Robot and camera positioning system/ Data save, fast size changing

RB600A Automatic Rigid Box maker

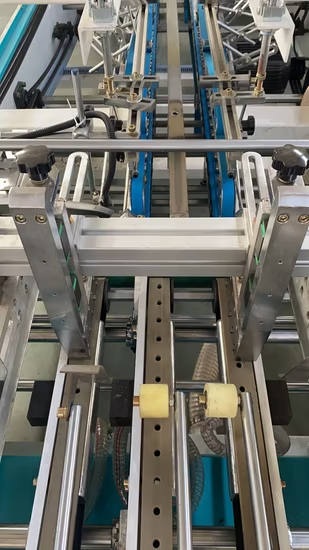

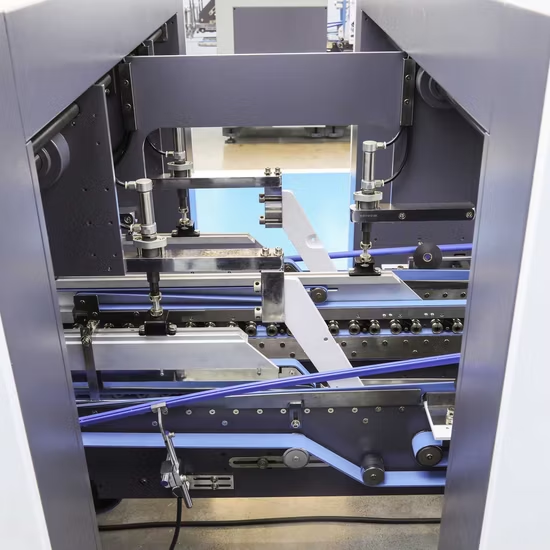

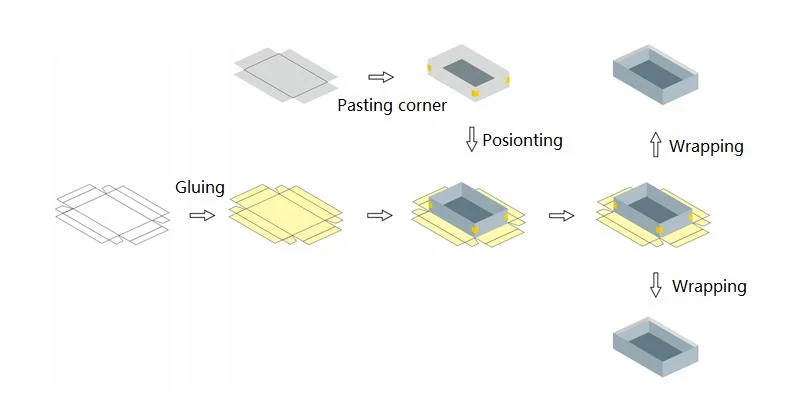

RB600A fully automatic rigid box maker, also known as automatic rigid box machines, is the highest-end rigid box production equipment. It employs high-speed motion controller, robot &camera positioning system, HMI to automatically finish feeding and gluing paper, conveying cardboard, forming and pasting four corners of cardboard, positioning, and wrapping box in one time. It is used in the field of high-grade packaging rigid boxes, involving electronic products, jewelry, cosmetics, perfumes, stationery, alcoholic drinks, tea, high-end shoes and clothing, luxury goods and so on.Features:(1) Automatic servo controlled paper feeder.

(2) Automatic circulation, mixing and gluing system of hot-melting glue with viscosity meter.

(3) Hot-melting paper/PET tape is automatic conveying, cutting, and pasting the cardboard box corners in one process.

(4) The vacuum suction fan under the conveyer belt can keep the glued paper from deviating.

(5) The glued paper and cardboard inner box employ Robot and camera positioning system. The positioning accuracy is ±0. 1mm.

(6) The box gripper can automatically collect and deliver the box to the wrapper without scratches.

(7) The wrapper is driven by servo system(20sets) which can continually delivery boxes, wrap, fold ears and paper sides and form the box.

(8) The whole machine employs PLC, robot positioning system and touch screen HMI to automatically form boxes in one process.

Production Flow:

The corresponding relationship between the parameters:

W+2H-4T≤C(Max) L+2H-4T≤D(Max)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

| Model | RB600A | |

| 1 | Paper size(A×B) | Min.100×140mm, Max.610×850mm |

| 2 | Box size(W×L) | Min. 50×100mm, Max.400×600mm |

| 3 | Paper thickness | 100-300g/m2 |

| 4 | Cardboard thickness(T) | 0.8~3mm |

| 5 | Box height(H) | 12-150mm |

| 6 | Fold-in paper size(R) | 10-100mm |

| 7 | Paper ear size | 10-100mm |

| 8 | Precision | ±0.10mm |

| 9 | Speed | <=30pcs/min |

| 10 | Paper Stack Height | 380mm |

| 11 | Board Stack Height | 1100mm |

| 12 | Motor power | 20kw/380v 3phase |

| 13 | Heater power | 10kw |

| 14 | Machine weight | 5500kg |

| 15 | Machine dimension(L×W×H) | L6360*W5000*H3260mm |

Remark:

1. The max and mini sizes of the boxes are subjected to those of the paper and the quality of the paper.

2. The speed depends on the sizes of the boxes.

Our Contact