High Speed Semi

Description

Basic Info.

| Model NO. | YK-2000 |

| Type | Corrugated Cardboard |

| Function | Transport Packaging, Storage and Packaging, Sales Packing |

| Packaging Technology | Corrugated Cardboard |

| Application | Drinks, Dairy Products, Cleaning, Detergent, Cosmetics, Skin Care Products, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning, Hair Care Products |

| Soft and Hardness | Semi-Rigid Package |

| Circulation Function | In the Packaging |

| Frequency of Use | Several Packaging |

| Mode of Operation | Packaging of Export Products |

| Name | Semi Auto Carton Box Stitcher Machine |

| Use | Cardboard Stitching/Nail |

| Delivery Time | 1 Month |

| Voltage | 380V/415V/440V |

| Transport Package | Standard Packaging |

| Specification | Standard |

| Trademark | YIKE Group |

| Origin | China |

| HS Code | 84413090 |

| Production Capacity | 50sets/Month |

Product Description

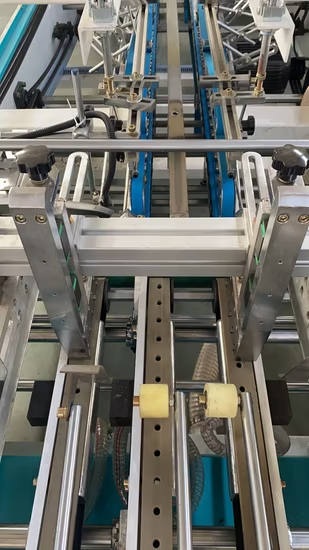

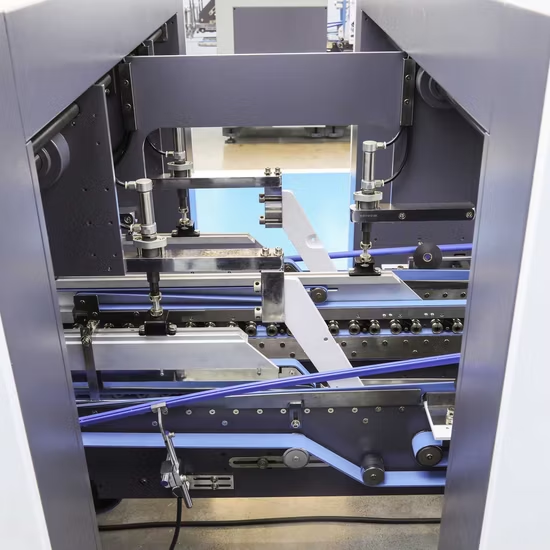

Semi-Auto Carton Box Stitcher Machine for Single Piece CardboardThe function and characteristic

Japan's Mitsubishi original imported dual servo drive with accurate accuracy and reduced mechanical transmission, which can effectively reduce the failure rate of the machine.

Mitsubishi touch screen operation, the parameters (nail distance, number of nails, nail type, back gate) can be changed quickly and easily.

The entire control system uses a Japanese Mitsubishi PLC control system.

The rear electric baffle is driven by a stepping motor, with accurate size and convenient size change.

The full contactor in the control box adopts the Mitsubishi brand.

Optoelectronics and proximity switches use the Schneider brand.

The bottom mold and blade are made of Japanese tungsten steel (wear-resistant).

The entire set of nail heads are made of special steel and precision processed by computer gongs.

Single nail /, double nail //, and reinforced nail (// / / // double nails on both ends are single nails in the middle) can be completed at one time, which can meet different customer requirements for different nail types

Changing the carton size and adjusting the carton nail pitch can be completed in one minute, which saves time and facilitates operation.

The front-end paper feeding section automatically counts, and the paper feeding table is equipped with a photoelectric sensor, which automatically rises when feeding paper.

There is an automatic counting function in the back section. The finished product can be stacked and sent to the end of the conveying machine according to the set number (1-99), which is convenient for packing.

Mechanical speed: 600 nails/minute.

Nail pitch: 30-120mm adjustable.

Electric adjustment of the gap between the pressing rollers.

Effective height of table lifting: 900mm.

Machine size: host 2.8x1.7x2.2 meters.

Machine weight: 1.5T.

The protection function of the electrical isolation transformer of the whole machine;

Automatic wire feeding system, 20KG flat wire, save time.

2 Specifications:

| MAX(A+B)X2 | 3600mm |

| MIN(A+B)X2 | 600mm |

| MAX C | 350mm |

| MIN C | 65mm |

| MIN (C+D+C) | 350mm |

| MAX B | 700mm |

| MIN B | 150mm |

| MAX A | 1100mm |

| MIN A | 150mm |

| TOTAL POWER | 4kw |

| MACHINE SIZE | 2800×2600mm |

| WEIGHT | 1500Kg |

| NAIL DISTANCE | 20-120mm |

| SPEED | 600Nail / minute |

| NAIL MODEL | 17,18 |

| NAIL QTY | 1-99 |

Our Contact